PRODUCT

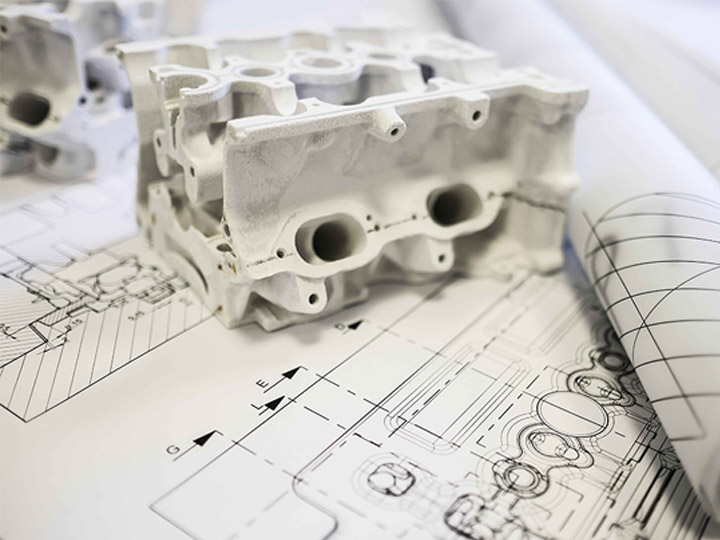

Mazzucconi contributes in a fundamental way to the development of the products that it supplies.

Starting from a draft project supplied by the customer and sometimes even from a white sheet, the team of Mazzucconi engineers – by means of complex modelling processes, simulation and structural calculation – optimizes the products in shape, weight and mechanical characteristics, fully respecting the strictest requirements regarding quality and reliability of today’s automotive industry.

This particular activity has intensified over the past years, especially with the increasing application of aluminium components in chassis and suspension applications.

Mazzucconi has developed the entire engineering process internally, allowing a close synergy between the product development and the production process.

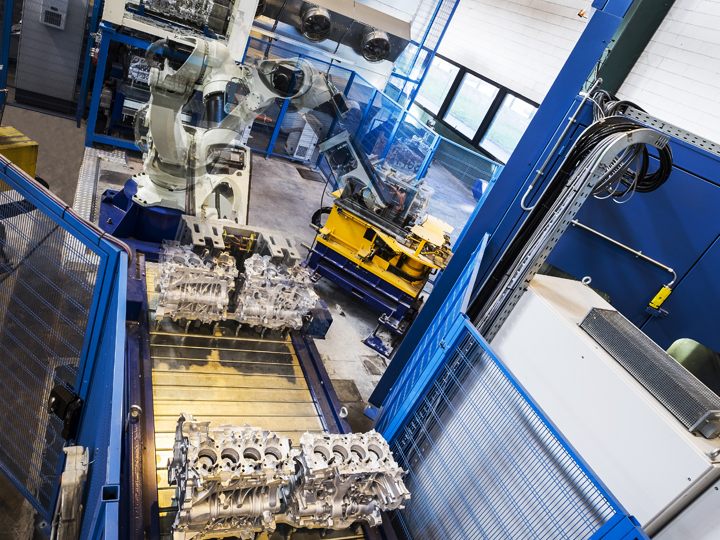

PROCESS

Mazzucconi utilizes in dedicated production sites the main casting processes for series production: high-pressure die casting, low-pressure die casting and gravity casting.

By means of the casting simulation, the engineers are able to integrate the development process of the single product while guaranteeing the full and constant feasibility.

Thanks to this way of proceeding, the potential problems in the production process can be avoided and a final product can be obtained that exceeds both mechanical requirements and the expected quality level.

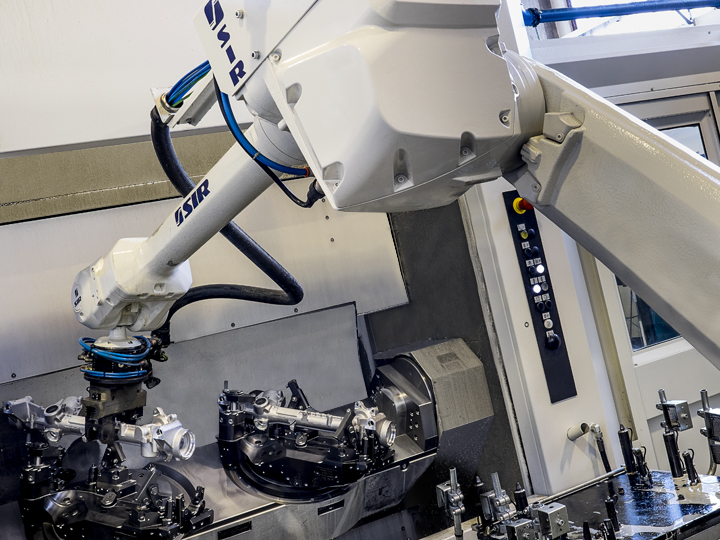

TOOLING

The major part of the tooling is developed and built in-house.

The Mazzucconi tooling shop produces tooling for high-pressure die casting, low-pressure die casting and gravity casting: molds, dies, core boxes and cutting tools.

The company’s competence in constructing tooling does not only guarantee the full compatibility between tooling, machinery and processes, but also optimizes the time-to-market of any requirement the customer might have.

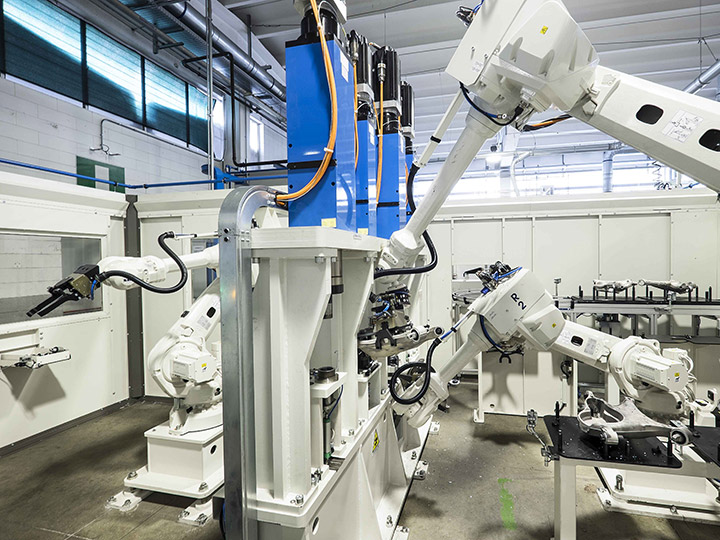

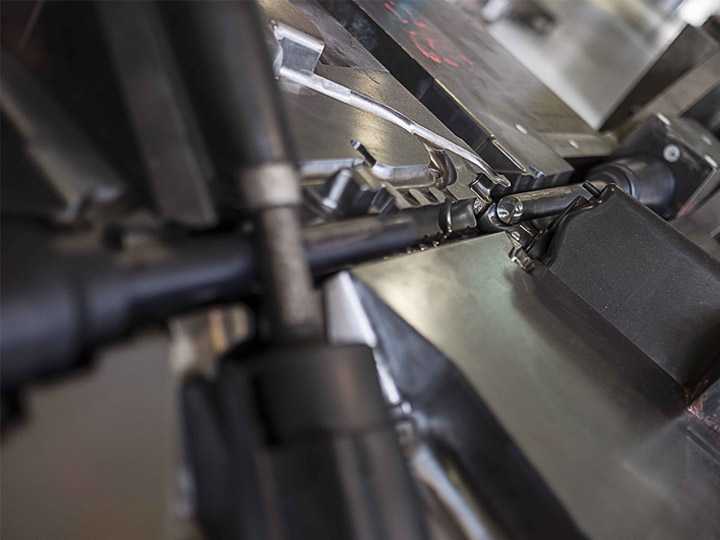

MACHINERY

The long experience in the production of semi-permanent mold components enables Mazzucconi to develop machinery adapted to vast number of requirements.

In gravity casting specific tilt-casting machinery has been developed, built and patented for the production of cylinder heads.

In low-pressure die casting, machinery has been developed and built with leading edge technology at the level of the most prestigious equipment producers in the industry.

This unique characteristic has allowed Mazzucconi to become a supplier of turn-key foundry equipment, including specific tooling, even for foundries of OEM vehicle producers in Russia and India.