COMPANY

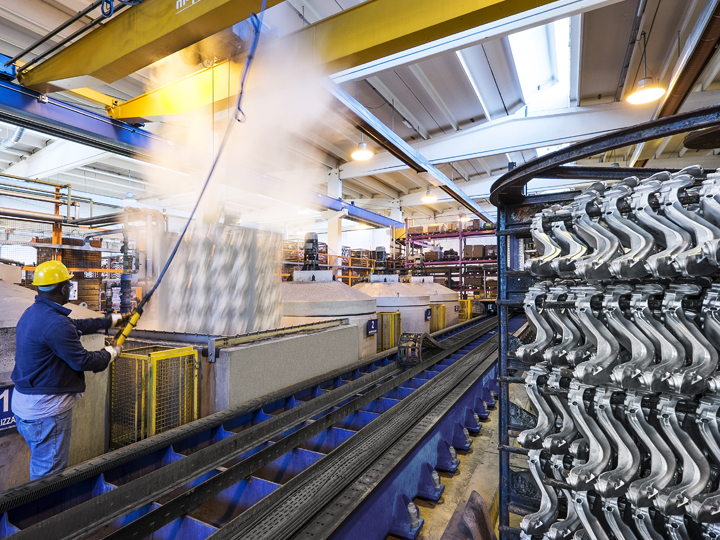

For over more than a century, Mazzucconi has been active in the field of metal castings and machining. Mazzucconi is located in Ponte San Pietro (Bergamo) and has seven production facilities located in Italy plus a local office in Munich, Germany. Mazzucconi produces aluminum alloy components, casted in gravity, low-pressure or high-pressure die casting, as well as fully machined and assembled components. The entire production is destined to the automotive industry. Mazzucconi can count on long-lasting relationships with some of the most important players in the industry.

The company is headed by the Mazzucconi family. From generation to generation they have cherished the experience matured throughout time, while at the same time aiming at a future made of innovation.

years of casting and metal working

production plants in Italy

office in munich

total employees 2017

110 YEARS OF CLASS LEADING CASTINGS

Over 110 years of history continue to inspire the company's activities today. The company's deeply rooted values continue to be part of the corporate strategy: commitment, passion for your work and care for the relationships with co-workers, clients and suppliers.1905

The Mazzucconi family starts its activity in the field of metal working.

1930

Besides the grey iron castings, the first aluminium castings were created; at that time an innovative material.

1955

Mario Mazzucconi heats up the first melting furnace of Fonderie Mario Mazzucconi S.p.A. in Ponte San Pietro (Bergamo), the company as we know it today, dedicated from the beginning entirely to aluminium alloy castings. The casting technology was sand casting.

1960

The gravity and high-pressure die casting technologies are introduced, as well as the start of alloy wheels production.

1970-1980

The automotive industry becomes the core business of the company and starting from the eighties, the company specializes in the production of cylinder heads, steering housings and gear box housings. The Valbrem S.p.A. company is established, entirely dedicated to alloy wheels production. The production site Ambivere is established, specifically dedicated to high-pressure die casting production.

1999-2000

Mazzucconi becomes a group with the acquisition of TEKAL in San Giovanni Teatino (Chieti), RONO in Almenno San Bartolomeo (Bergamo) and Fonderia San Possidonio in San Possidonio (Modena).

2000-2003

At the start of 2000s, the consolidated co-design activities are expanded and the company reaches the capacity of developing components. Go to production first projects containing machining as well as assembly, like cylinder heads.

In 2003 the company Speedline was acquired, a leading producer of alloy wheels for passenger and commercial vehicles. In 2007, Mazzucconi decides to exit wheels production and sells both Speedline and Valbrem to the Swiss Ronal AG.

2009-2014

The global crisis in the automotive industry forces Mazzucconi to apply for the 'concordato preventivo di continuità' procedure. The turnover drastically falls from 170 million euro in 2007 to 70 million in 2009. Notwithstanding the numerous difficulties, the Group continues to respond with dynamism and in the first years of the crisis, new important projects of suspension arms and knuckles in low-pressure die casting go into production. These new projects are fundamental for the increase of turnover and, in fact, Mazzucconi closes 2014 with a turnover of over 150 million euros and ends the procedure positively.

2015

After having successfully survived the years of crisis, a new phase of development starts with the acquisition of numerous new projects for new and existing clients in powertrain, suspension and steering systems. The production of inorganic sand cores starts, a new technology that only few foundries in the world utilize in series production.

PRODUCTION PLANTS

Ponte San Pietro

10.000 mq area

165 employees

Ambivere

13.000 mq area

260 employees

San Possidonio

10.000 mq area

200 employees

Rono

17.000 mq area

275 employees

Simi Peterle

5.000 mq area

100 employees

Tekal

10.000 mq area

200 employees